Automation INspection

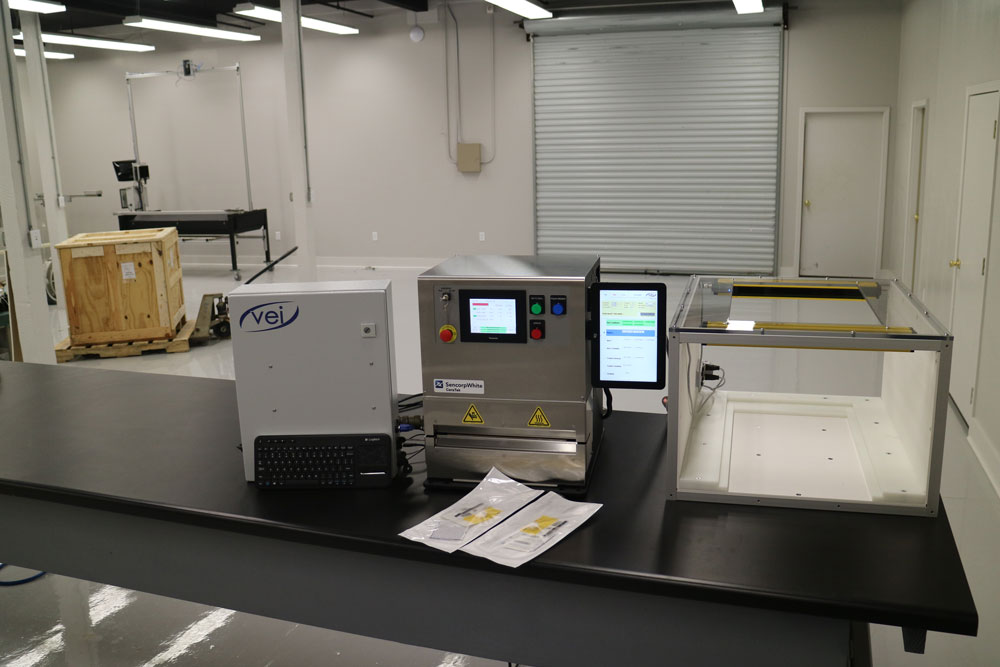

VEI’s automation inspection systems interface with a number of automated packaging processes providing robust quality control & protection measures. Automated packaging processes offer several benefits including improved throughput & greater consistency but are often lacking means of ensuring packaging conformance. VEI solutions monitor both the machine parameters as well as packaging details including: part identification, label inspection, and other facets to ensure conformance.

Sealer Process Verification

Sealer, FFS and Autobagger integrated Inspection Systems

Seal Process Verification

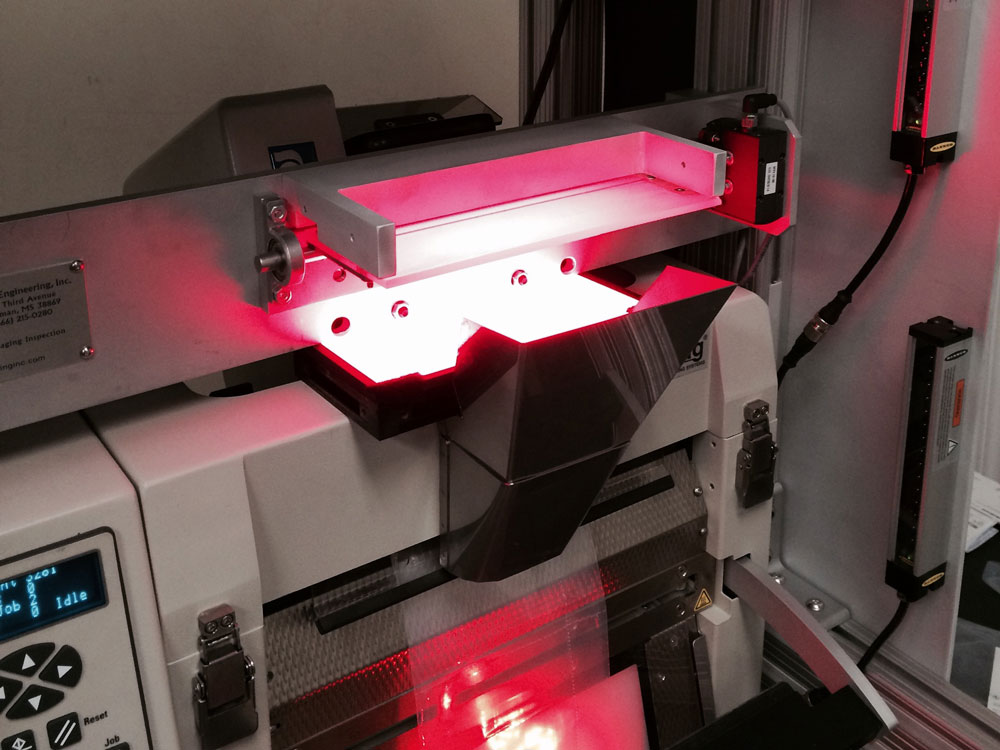

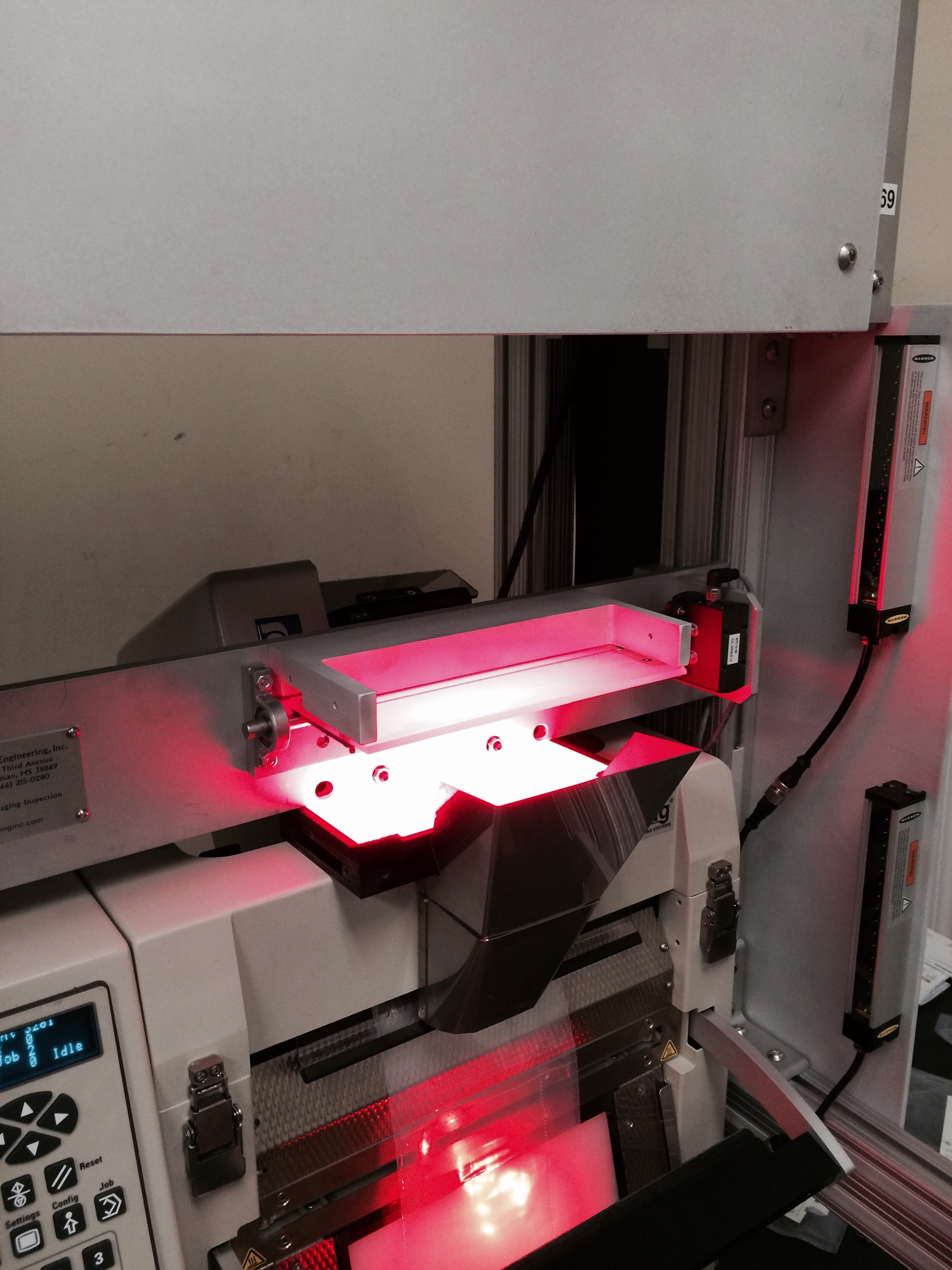

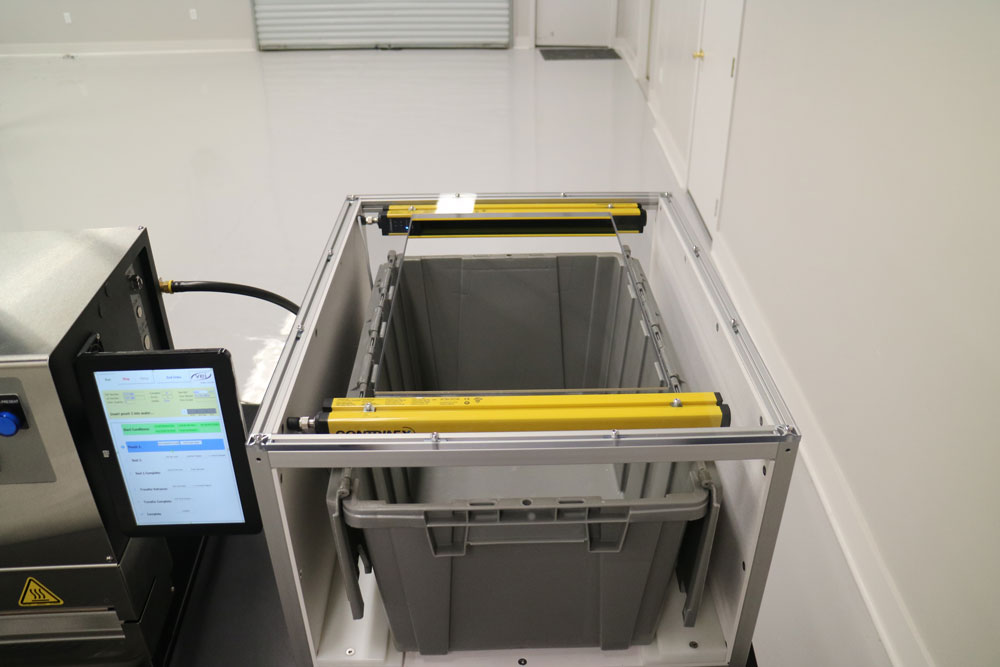

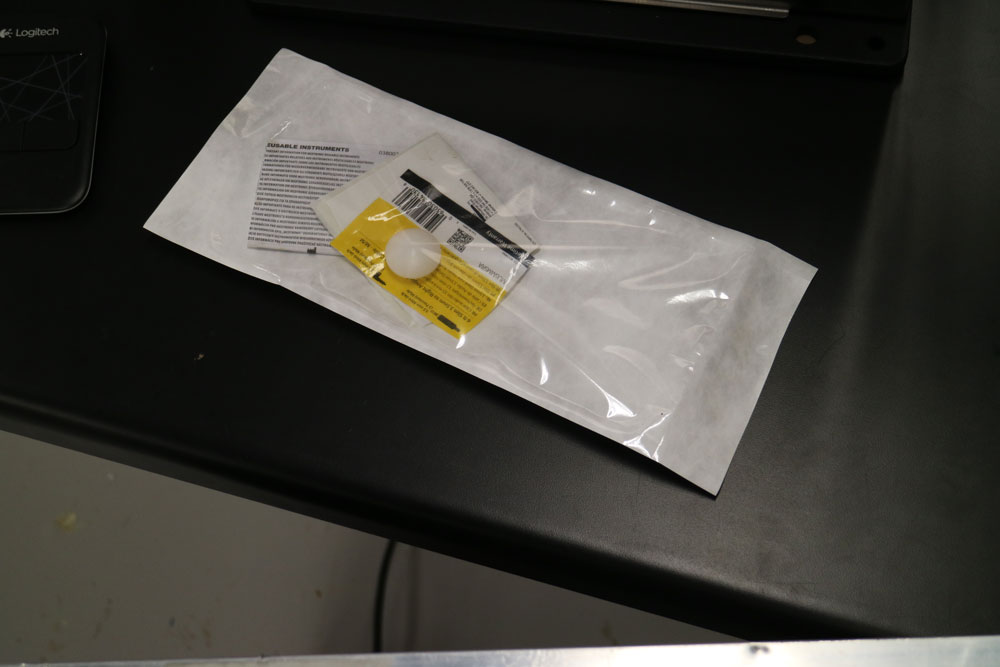

Seal Inspection: Our Sealer Verification inspection platform provides assurance that packaging operations process flow and sealer parameters are set within specified bounds. More specifically the system ensures that operators follow the correct sequence of events when packaging products in Tyvek pouches including initiation of seal, seal completion, and transfer to packaging bin. Likewise, the sealer’s settings are monitored to ensure conformance with operational quality guidelines as well as that a pouch was truly present during the sealing process. As such, Sealer Module eliminates many errors associated with sealing operations such as unsealed pouches and discrepancies between order quantity and actual quantity.

Autobagger Module

VEI’s Autobagger Module is used to eliminate product mix situations as well as ensure conformance in packaging of labels, IFU’s & the device itself. This is accomplished by performing dimensional checks of the part (part identification), detection of part presence in pouch, IFU item number identification and detection of IFU presence in pouch. Furthermore, automatic reports of each packaging process are generated and archived for future use. Additional options are also available.