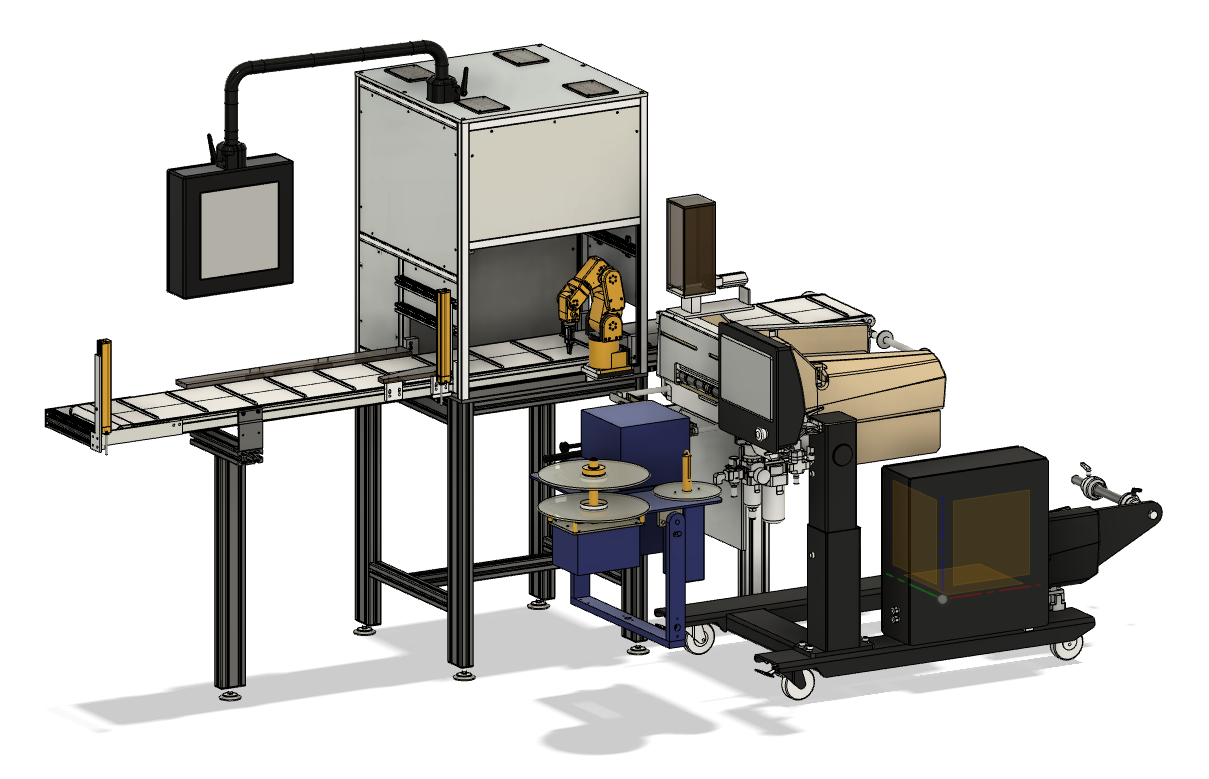

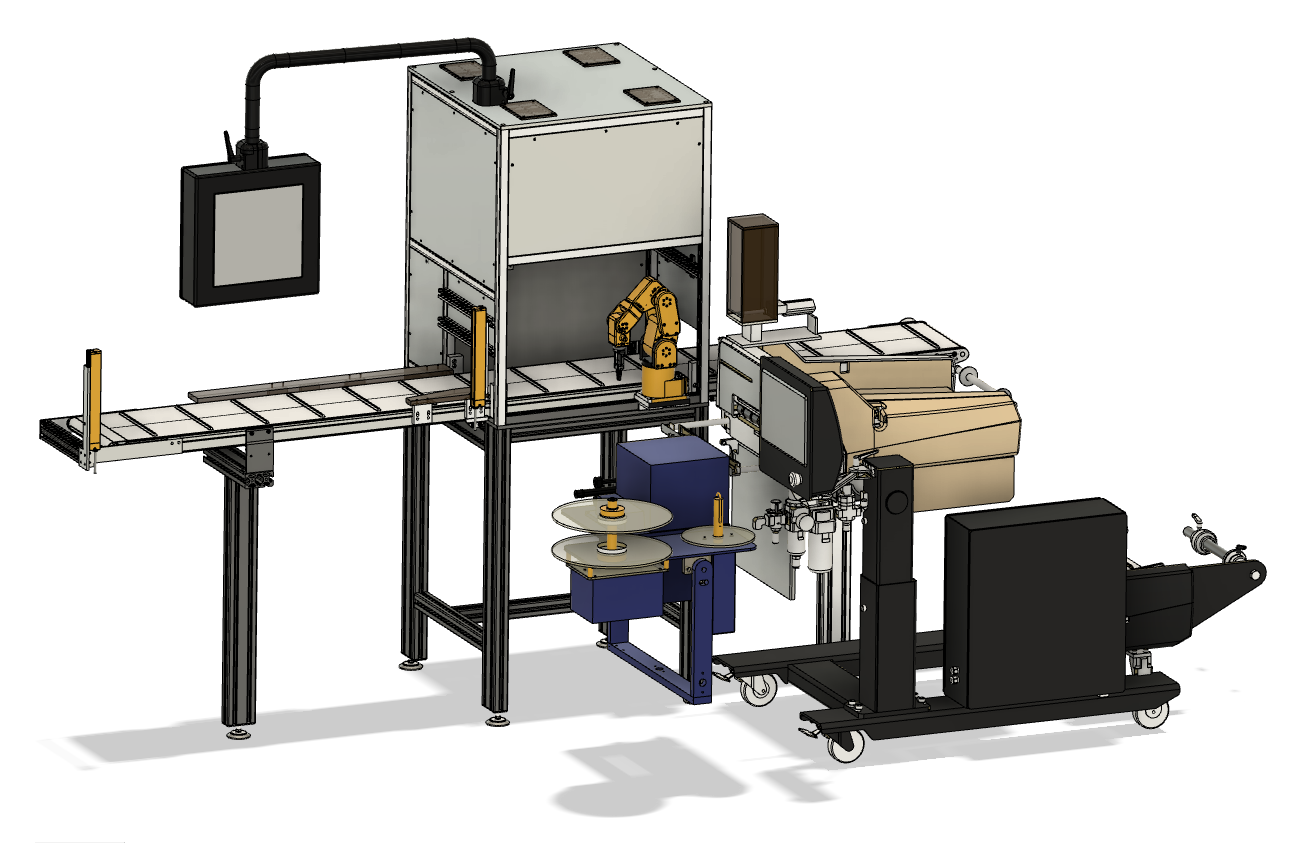

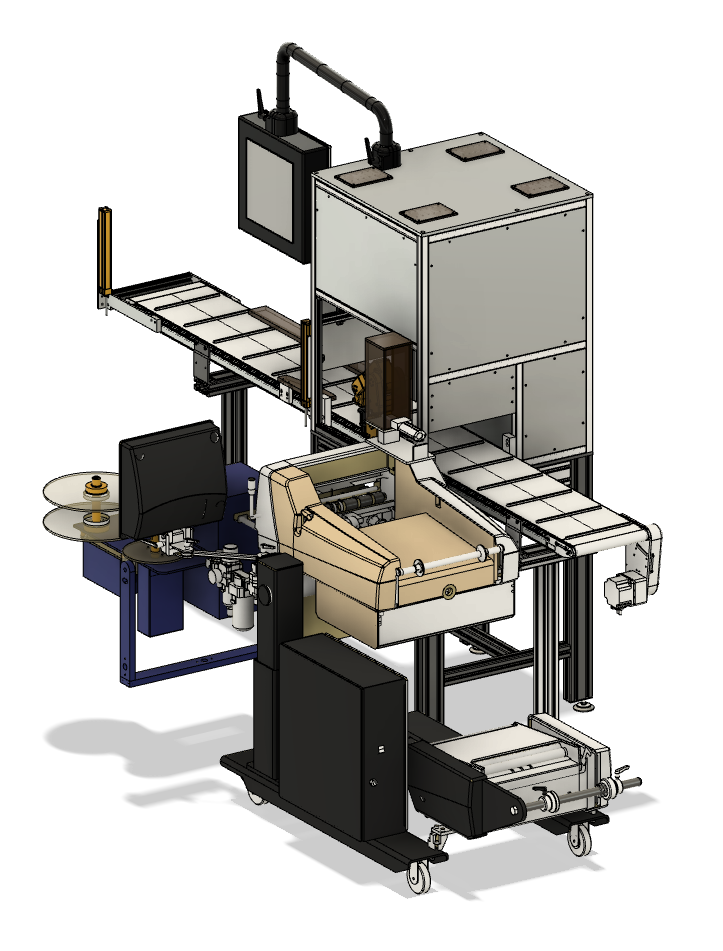

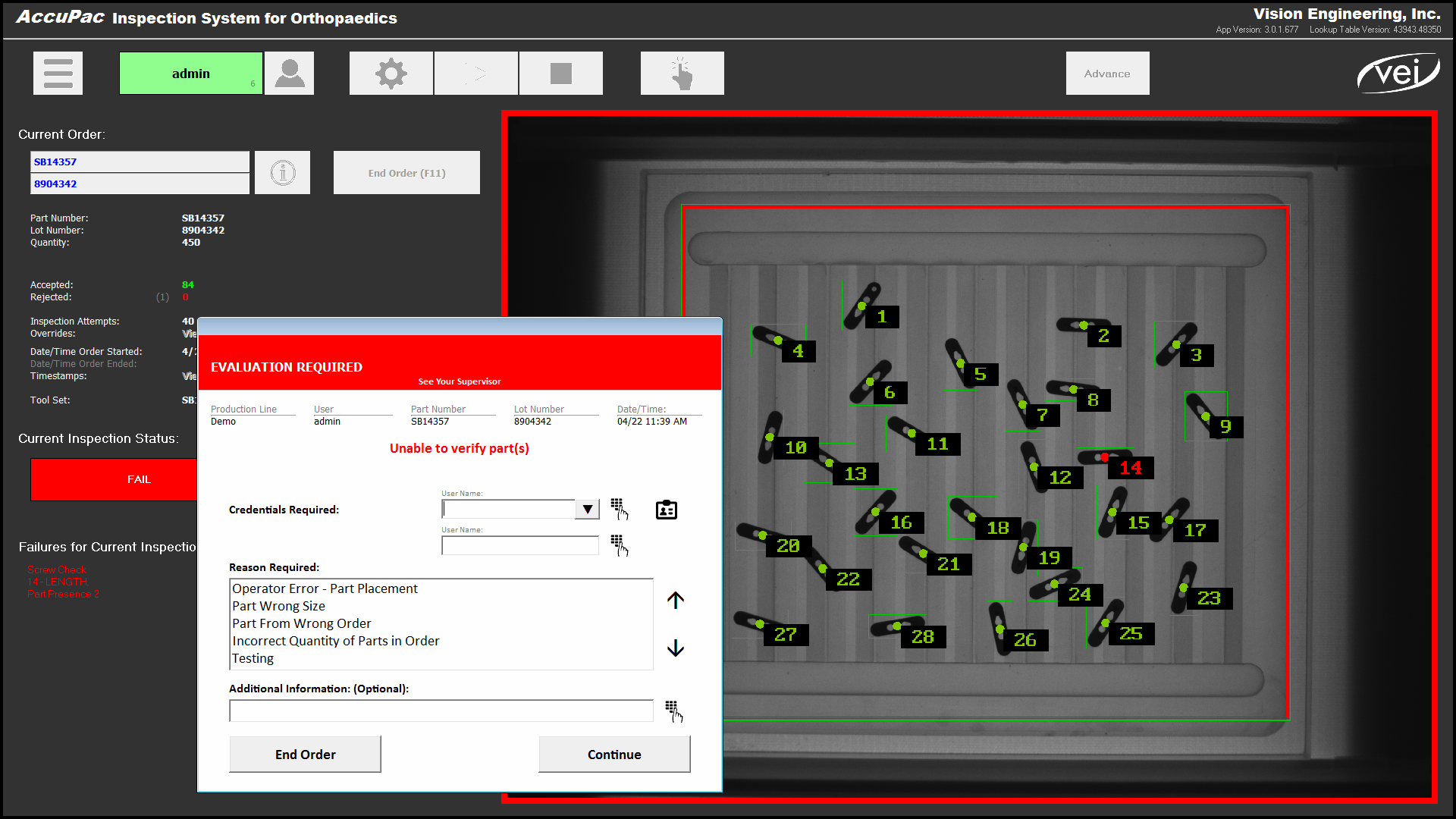

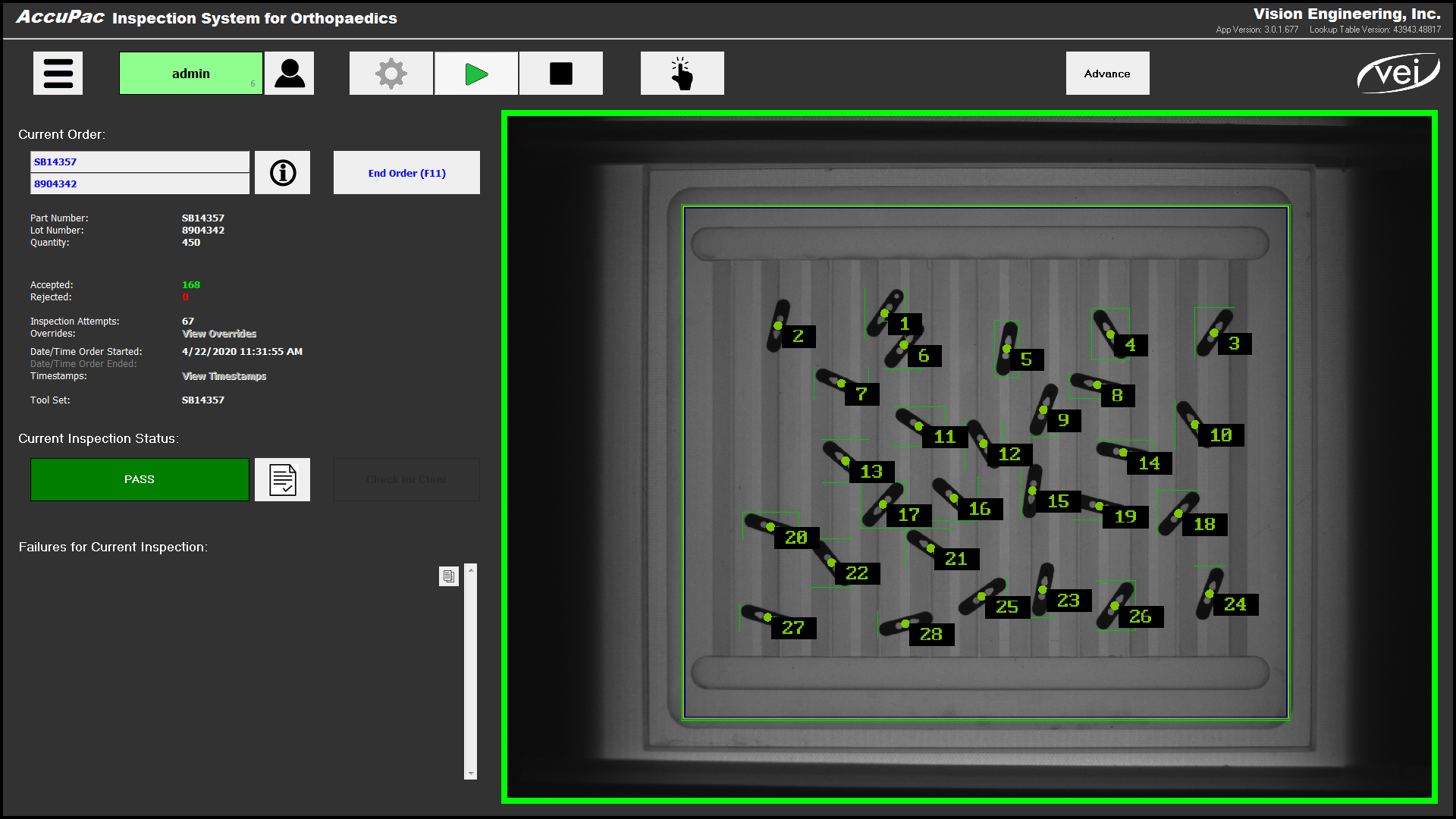

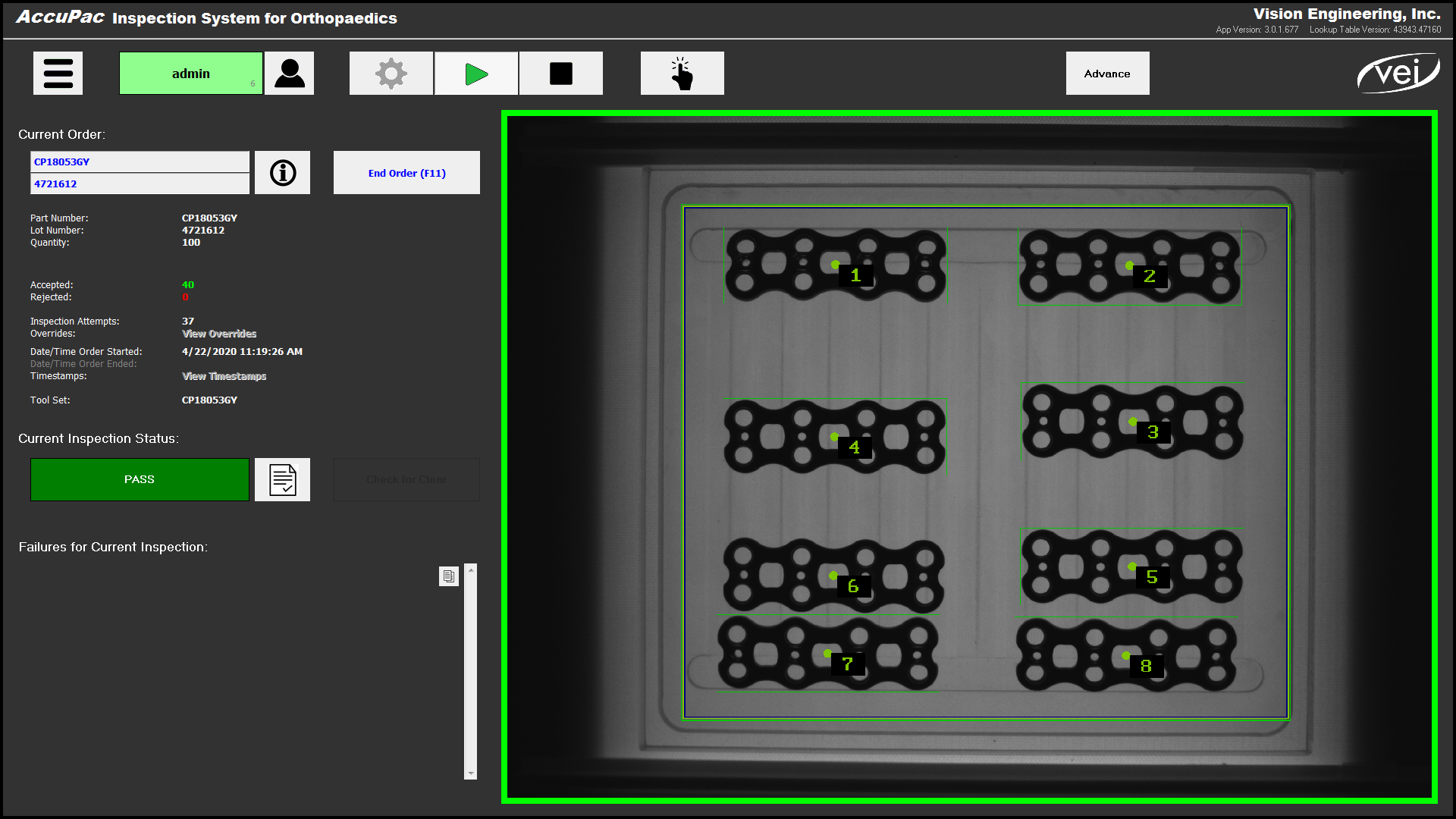

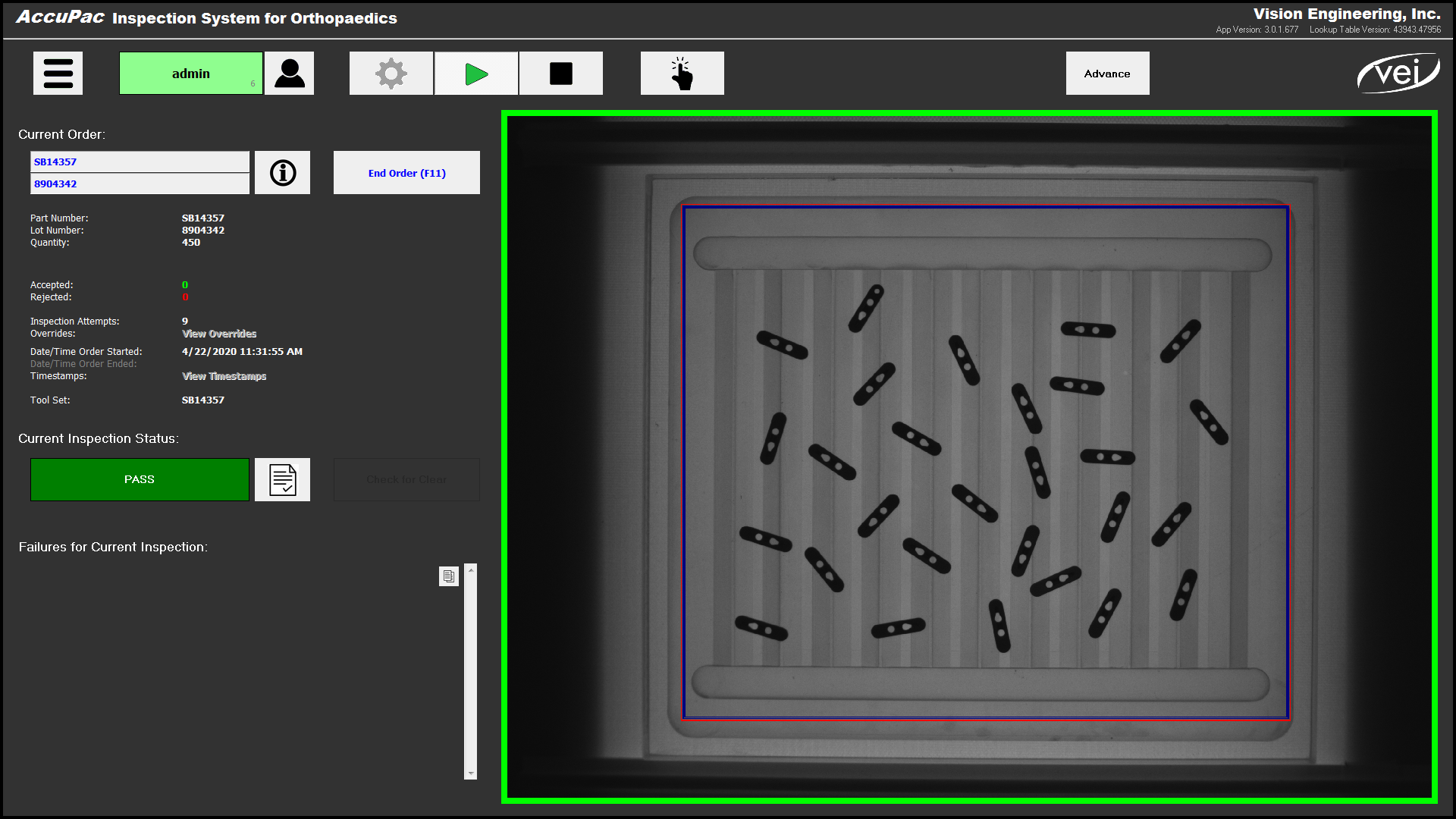

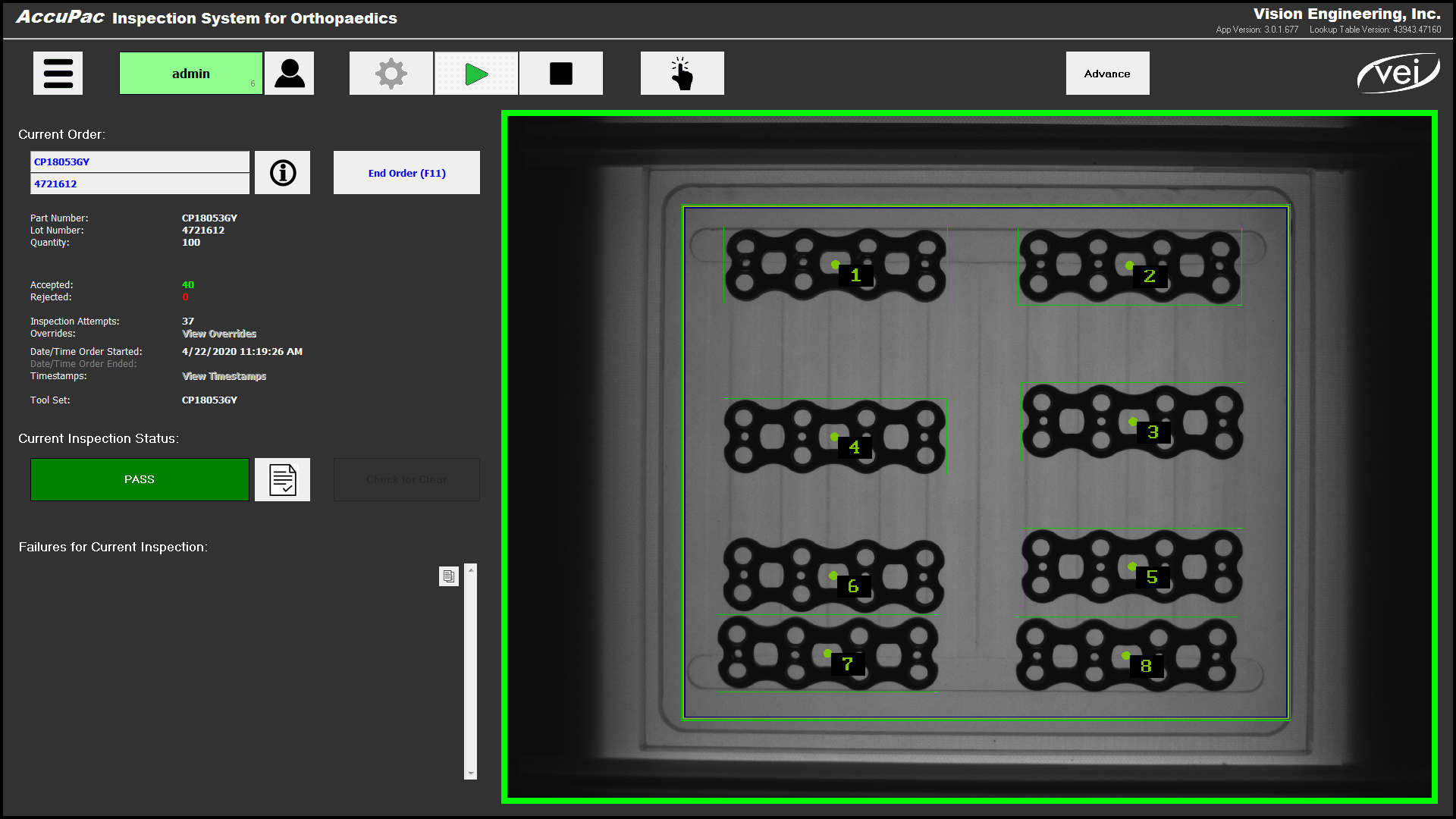

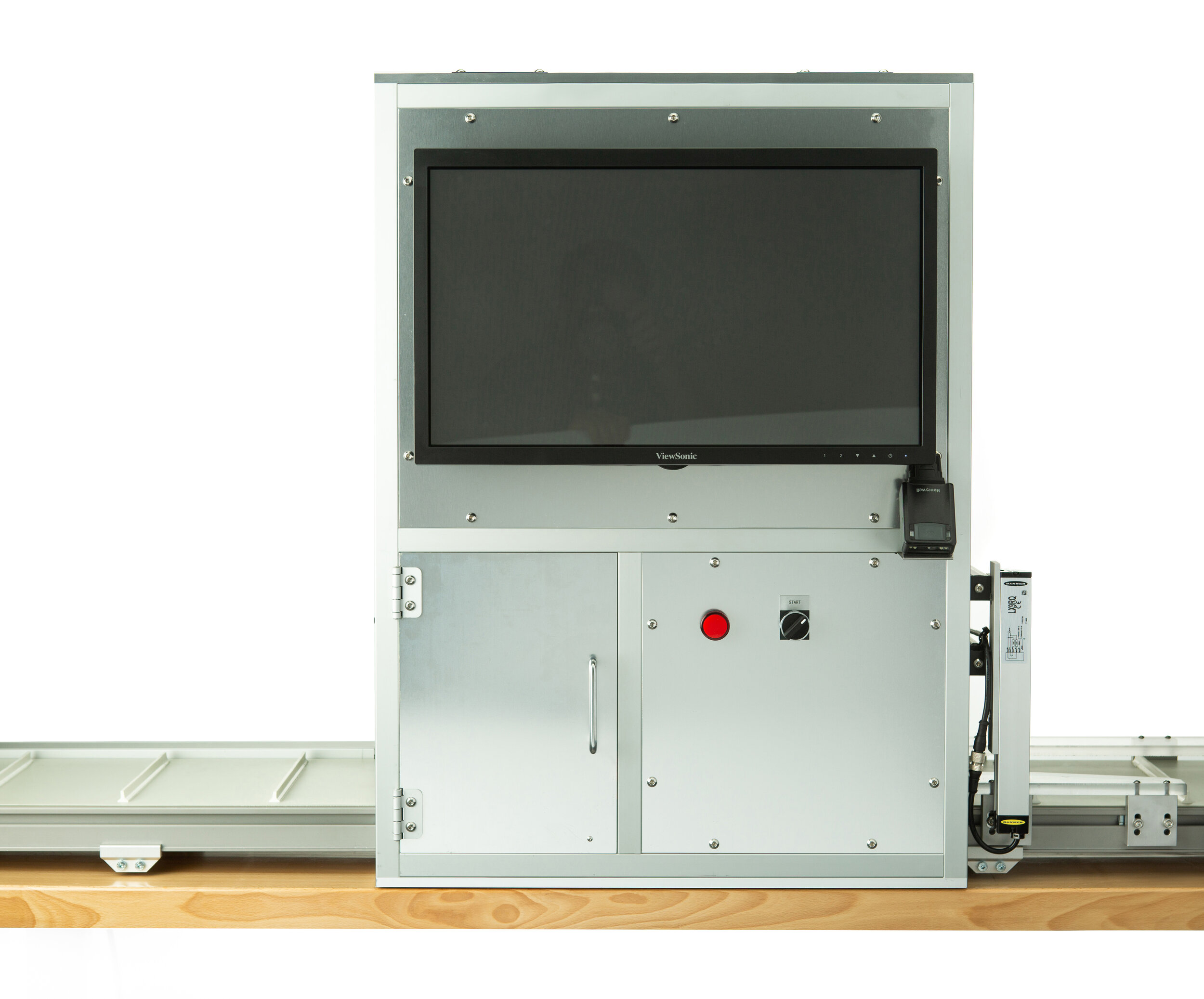

The VMOD-2000SC is a conveyor-based inspection system typically deployed in batch processing applications where minimal operator interfacing with the system is desired. The system allows the operator to load an entire lot of parts in trays on the infeed side of the conveyor. Once parts are loaded an order can be started by scanning a routing document and placing the system in run mode. The system inspects and indexes only stopping when non-conforming part/parts are encountered by the system. When non-conforming parts are encountered the system ceases operation and requires a credentialed override. This override screen requires a password protected login and reasoning behind the failure, this ensures that any non-conforming parts are quarantined and documented at the at the system with a full audit trail reflected on the report. Any parts that exit the outfeed of the system have been verified and are correct for the order that was initiated on the system.